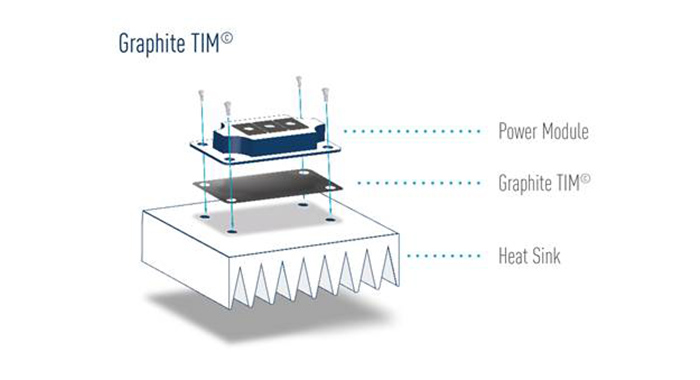

Panasonic has come up with a material called Graphite TIM (Terminal Interface Material) for dissipating heat from power modules operating in harsh industrial and automotive applications.

Mounted on dedicated heat sinks, heat dissipation is traditionally achieved with a particular layer of grease – that, of course, has to be replaced from time to time which is a labour-intensive frequent task, next to the fact that grease naturally doesn’t stay only where it is applied. That, in turn, counteracts an effective thermal dissipation.

These are the issues addressed by Graphite TIM. Now, the renowned manufacturer has released its highly compressible EYGR type, reducing the thermal resistance by filling the gap and the unevenness on the surface of both power module and heatsink, and thus enhancing the thermal dissipation performance.

With a thermal resistance of 0.2 K∙cm2/W (at 600 kPa) and a thermal conductivity in X-and Y- direction from 200 to 400 W/m∙K, respectively 28 W/m∙K in Z-direction, the Panasonic Industry Graphite TIM types are a promising option for the reliable cooling by high heat transferring performance and wide operating temperature range from -55 to 400℃ for power module in many electronic devices:

Inverters, converters, automotive control units, medical equipment or server infrastructures will clearly profit from an increase in reliability, longevity and service easiness.